Tower hoists are an essential component of equipment that move workers, materials, and other objects to different levels of a building or other structure at a construction site. Tower hoists reduce the need for manual labour and the probability of accidents, which can significantly increase the efficiency and safety of a construction project.

Tower hoists come in different sizes and configurations to suit various site conditions and construction needs. They can be installed either inside or outside a building and can be equipped with advanced safety features and technologies, such as overload sensors and emergency stop buttons, to ensure the safety of workers and materials.

A tower hoist is typically built first at a construction site before any other work is done. It is an essential part in modern construction projects, and their application has completely changed the way that projects are carried out. They have significantly improved speed, safety, and efficiency, making them an essential tool in the construction sector.

4 Types of Tower Hoists and their uses

Tower Hoists with H-Frame

H-frame tower hoists are a vital component of the construction industry. They are intended to add to the hoist’s stability and support, making it more secure and unlikely to fall over. The load is evenly distributed across the base of the hoist due to the additional rigidity and support provided by the steel H-frame, which is attached to the base of the hoist.

Construction projects requiring heavy lifting, tall structures, or complex shapes frequently use tower hoists with H-frames. They are perfect for moving workers, supplies, and equipment between floors of a building or other structure. These hoists are useful in the construction industry because of their adaptability and versatility.

Uses:

1. High-rise construction: When lifting people or objects to heights, tower hoists with H-frames are frequently used. These hoists are used to move workers, equipment, and building supplies between floors of the structure.

2. Bridge construction: Tower hoists with H-frames are also used in projects involving building bridges. In these projects, the hoist must be positioned on the side of a bridge to move workers and construction supplies to various locations on the bridge.

3. Construction of skyscrapers: Tower hoists with H-frames are frequently used, and the hoist must be tall enough to reach the upper floors of the building. These hoists are frequently used to move supplies, equipment, and personnel between floors of the structure.

Tower hoist without H-frame

Tower hoists without H-frames are a specific kind of tower hoist that is made to be portable, adaptable, and simple to install. These hoists are frequently used in construction projects where site conditions have limitations or where the hoist must be moved frequently.

Four vertical legs attached to the base of the hoist give stability and support for tower hoists without H-frames. These hoists can be used for a variety of construction projects because the legs can be adjusted to the site’s conditions.

Uses:

1. Renovation of buildings: When the hoist needs to be placed in constrained spaces or narrow alleys, tower hoists without H-frames are frequently used. These hoists are a practical choice for transient construction projects because they are simple to set up and take down.

2. Dam construction: To move bulky equipment, like concrete blocks and steel plates, to various levels of the dam, tower hoists without H-frames are employed. These hoists are flexible and adaptable, making them perfect for construction projects that call for mobility and adaptability.

3. Shipyard construction: Tower hoists without H-frames are used in shipyard construction projects to transport ship components, such as engines and propellers, to different levels of the ship. These hoists are easy to install and dismantle, making them an excellent option for temporary construction projects.

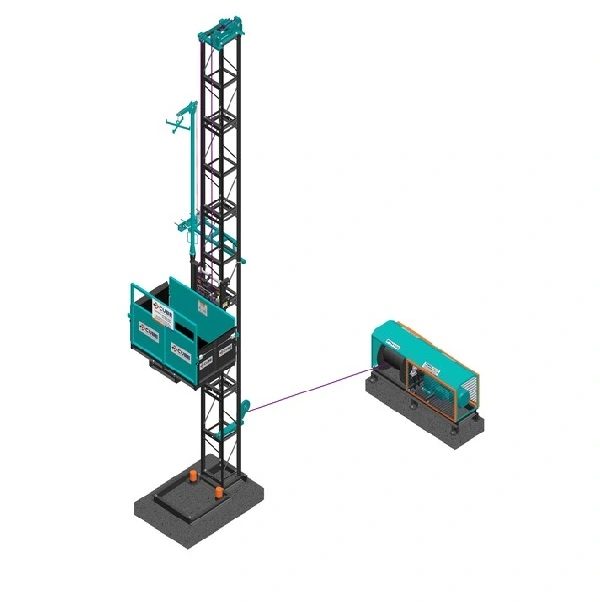

Multi-functional Tower Hoist

Tower hoists that can perform multiple tasks in the construction industry are known as multi-functional tower hoists. These hoists are outfitted with cutting-edge technology that enables them to carry out a variety of tasks, making them a crucial part of contemporary construction projects.

Tower hoists with multiple uses are made to be efficient, adaptable, and flexible. They can carry out a variety of tasks, including lifting, lowering, and rotating materials and equipment, thanks to their telescopic masts, numerous lifting mechanisms, and sophisticated control systems.

Uses:

1. Lifting heavy loads: Multi-purpose tower hoists are capable of lifting heavy loads to various floors of a building or other structure. They have sophisticated lifting equipment that enables them to lift loads weighing several tonnes, such as hydraulic cylinders and electric winches.

2. Painting and cleaning: The exterior of buildings can be painted and cleaned using multi-purpose tower hoists. In order to efficiently paint or clean hard-to-reach areas of a building or structure, they can be fitted with platforms that give workers access to those places.

3. Plastering and concrete spraying: Spraying plaster and concrete onto the walls of a building or structure is possible with the help of multi-purpose tower hoists that are fitted with specialised attachments like spray nozzles. This enables quick and effective plastering or spraying over large areas.

Monkey Hoist:

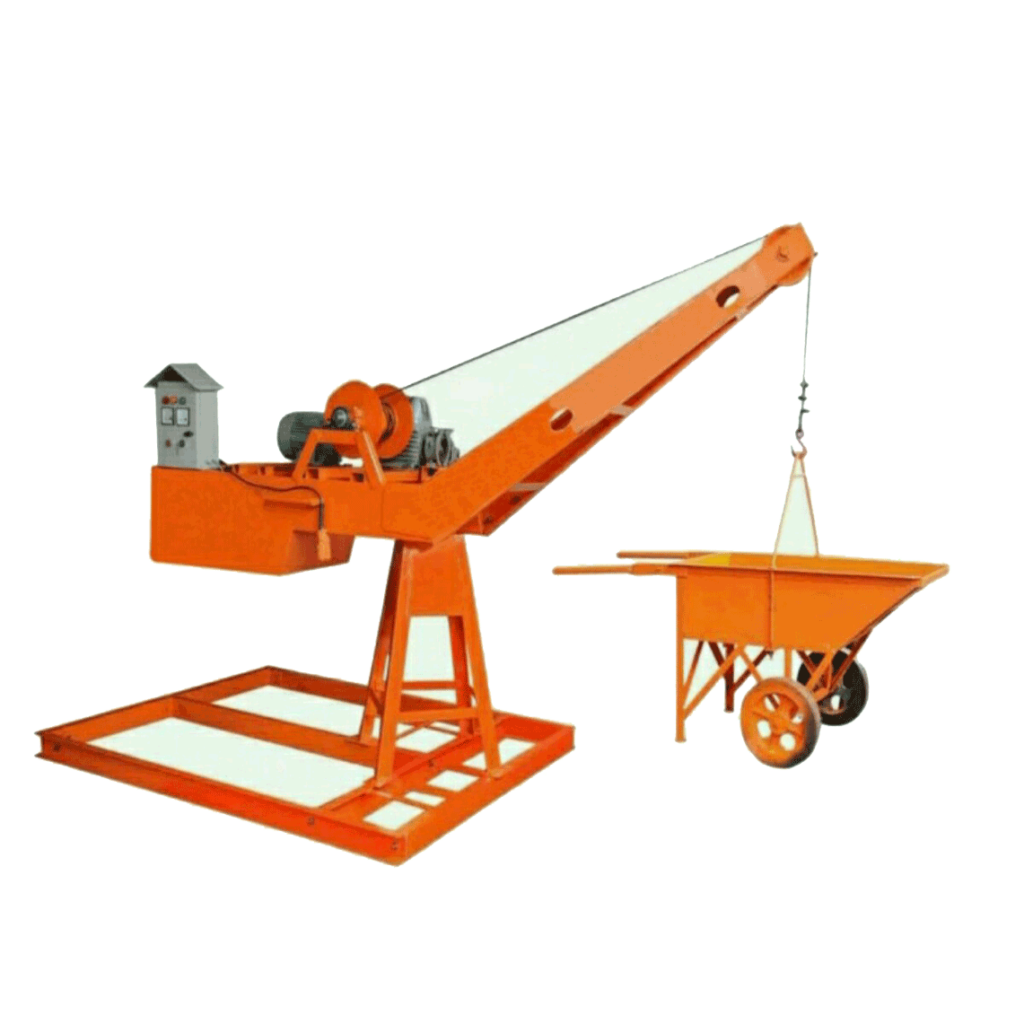

A monkey hoist, also referred to as a rope hoist or a builder’s hoist, is a straightforward and affordable lifting tool that is frequently used in the construction sector. It is intended to lift or lower supplies and machinery to various floors of a building or other structure.

A motorised winch that is fastened to a frame or other support structure makes up the monkey hoist. The winch, which is used to raise and lower loads, is connected to a wire rope or cable. A worker typically operates the hoist by using a control panel to direct the load’s direction and speed.

A reliable and affordable lifting tool that is frequently used in the construction sector is the monkey hoist. It offers a quick and secure way to lift objects.

Uses:

1. Window and door installation: High-rise buildings’ windows and doors can be installed using monkey hoists. They make it possible to quickly and safely install heavy glass panels and doors by lifting and positioning them to the necessary height.

2. Carrying tools and equipment: Monkey hoists can also be used to transport tools and equipment to various levels of a building or other structure. Heavy tools and equipment that would be difficult to carry manually can be transported effectively and safely using them.

3. Moving debris: There is frequent waste and debris on the construction site that needs to be removed. This waste can be moved to the ground level using monkey hoists, making disposal simpler.

Conclusion,

Tower hoists are clearly an important part of contemporary construction projects when one takes into account their various types and uses. Tower hoists are a vital tool in the construction industry because they greatly increase a project’s safety, effectiveness, and speed.

Smit Corporation’s tower hoists are designed to increase efficiency and safety in construction projects, and they have been proven to be an essential tool in the construction industry.

The best tower hoist dealer in Gujarat, Smit Corporation, offers a variety of tower hoists that can meet various site conditions and construction requirements. To ensure the safety of workers and materials, they offer high-quality, effective tower hoists that are fitted with cutting-edge safety features and technologies.

Smit Corporation can offer the best option for your construction needs, whether you need a tower hoists with H-frames, without H-frames, a multi-functional tower hoist, or a monkey hoist.